Roll forming machines, indispensable in today's industrial production processes, are crucial equipment offering a wide range of applications in va...

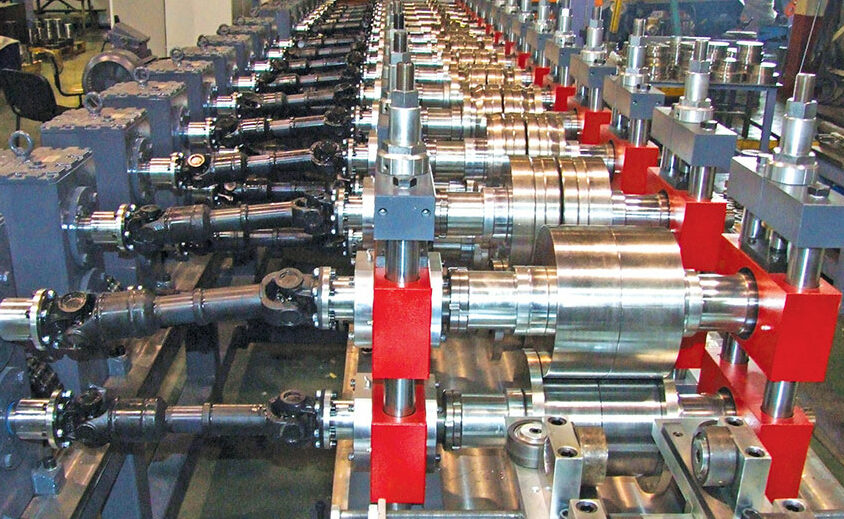

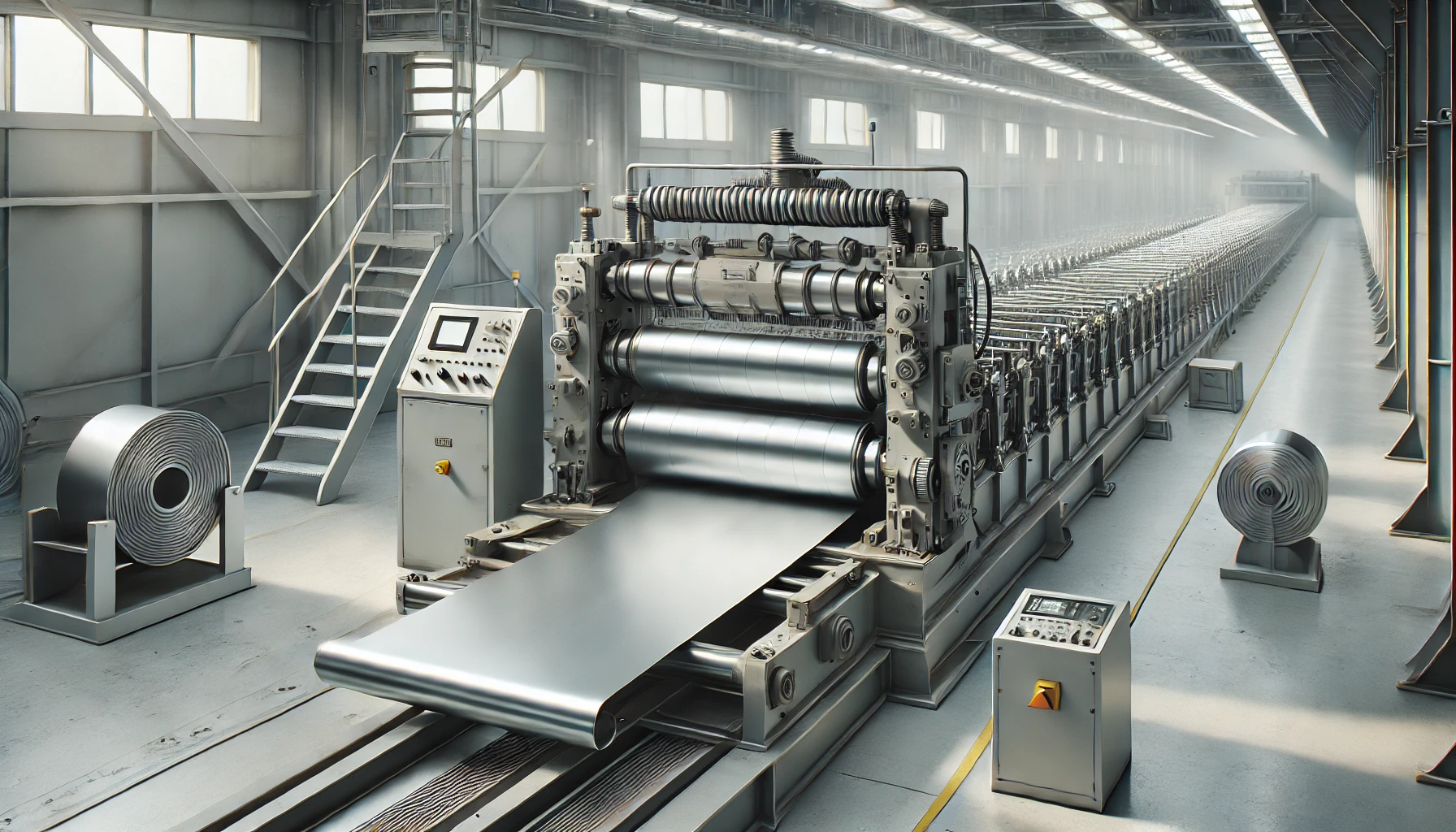

A roll forming machine is a machine that continuously shapes metal sheets into a specific profile. These machines pass the metal sheet through a series of consecutive rollers to achieve the desired shape. As a result, the metal sheet is shaped into the required profile. Roll forming technology is widely used, especially in the production of structural elements that require long-lasting durability. The precision, durability, and efficiency offered by this technology make it a preferred choice across various industries.

What is a Roll Forming Machine?

Roll forming is a manufacturing technique that gradually bends a flat metal sheet into a specific form step by step. A roll forming machine is the machine that performs this process and is typically used to shape metals like steel or aluminum. These machines work through a continuous process, providing high production speed and quality. As the metal passes between the rollers at the front of the machine, it is shaped at each stage to reach the desired form. The machine changes the shape of the material without cutting or drilling, simply altering the form of the metal.

Usage Areas of Roll Forming Machines

Roll forming machine technology has a wide range of applications across many different industries. Below are some common areas where this technology is widely used:

1. Construction Industry

The construction industry is one of the most common sectors where roll forming machines are used. Roofing materials, gutters, façade claddings, and various structural profiles are produced using roll forming technology. These machines enable fast and cost-effective production of metal building elements used in construction projects.

2. Automotive Industry

Roll forming also has a wide application in the automotive industry. It is particularly used in the production of automotive parts and accessories. Vehicle chassis, frame components, and door frames are produced using roll forming machines. In the automotive manufacturing process, where high precision is required, roll forming technology ensures quality in metal shaping.

3. Energy and Electrical Industry

Electric poles, structural elements used in power plants, and cable management systems are produced using roll forming technology. Additionally, frames and support elements for solar energy panels are also shaped with this technology. In the energy sector, where durability and long-lasting materials are essential, roll forming machines provide an ideal solution.

4. Furniture and Home Decoration

The furniture industry uses roll forming technology to meet aesthetic and durability requirements. Various metal profiles used in furniture production are manufactured with roll forming machines. Metal shelving systems, decorative frames, and furniture accessories are shaped using this technology.

5. Infrastructure and Logistics Systems

Roll forming machines play a significant role in the production of structural elements used in various infrastructure projects and logistics systems. Highway guardrails, bridge structural components, railway tracks, and similar infrastructure projects benefit from roll forming machines.

Advantages of Roll Forming Machines

The advantages offered by roll forming machines make them widely preferred in industrial production. Here are the main advantages of these machines:

1. High Efficiency

Roll forming machines operate through a continuous process, providing high production speed. This allows for large-scale production, reducing costs. In large-scale projects, roll forming machines offer great advantages due to their high production capacity.

2. Precise Shaping

Roll forming machines can shape metal sheets with high precision into the desired profile. This precision is especially important in the production of complex profiles. In sectors like automotive and aerospace, where high precision is required, roll forming machines are preferred.

3. Material Savings

Roll forming machines allow the material to be folded and shaped, resulting in minimal material waste. This helps reduce costs and increases production efficiency.

4. Durability and Longevity

Metal profiles produced with roll forming machines have high strength. This contributes to the durability of structures, making it a preferred technology in the construction sector. Additionally, the long lifespan of materials produced with this technology reduces maintenance costs.

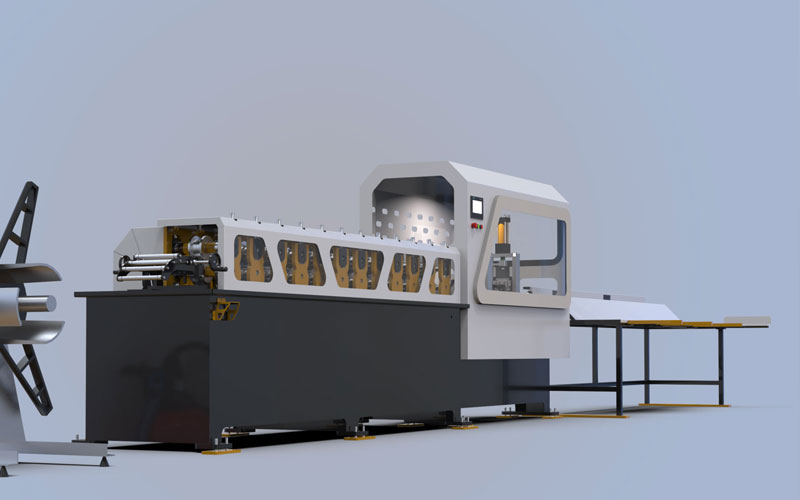

5. Automation and Integration Capability

Today, roll forming machines can be integrated with automation systems. This allows production processes to become more efficient. With automation, production errors are minimized, and the need for manual labor is reduced.

A roll forming machine is a technology that offers high efficiency, precision, and durability, especially in the production of metal structural elements. It is widely used in sectors such as construction, automotive, energy, and furniture. Roll forming machines, operating with a continuous process, increase production capacity, provide material savings, and offer high precision in the production of complex profiles. Therefore, roll forming machines are an ideal solution for companies seeking high efficiency and quality in industrial production.